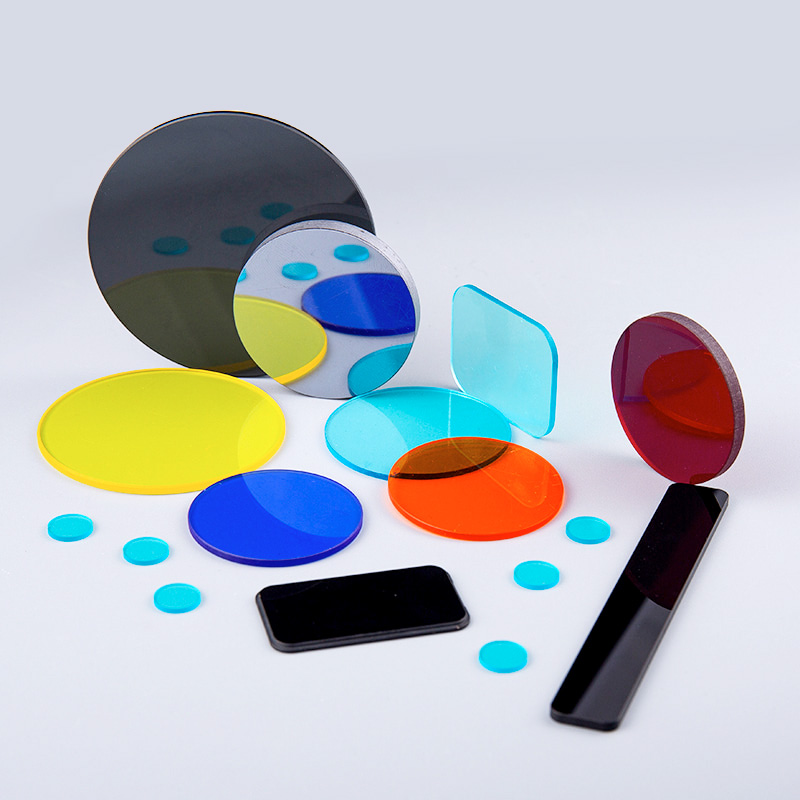

Optical glass filters are the unsung heroes of precision work. Whether you’re an astronomer capturing distant nebulae, a photographer crafting the perfect shot, a scientist conducting spectral analysis, or a laser technician aligning a beam, the clarity of your filter is paramount. It sits in the optical path, meticulously shaping light to deliver a perfect image or data set. Yet, this critical surface is incredibly vulnerable. Among all the potential contaminants—dust, pollen, moisture—few are as insidious and damaging as the humble oil stain.

The problem of oil on optical surfaces is a common frustration. It can originate from a surprising number of sources: a single fingerprint during handling, aerosols from lubricated machinery, skin care products, or even cooking fumes in a home environment. These stains are more than just a cosmetic nuisance; they are a direct threat to performance. They scatter light, reduce contrast, induce flare and ghosting, and can permanently etch into delicate coatings if not addressed properly.

Dealing with this issue requires a methodical, gentle approach. This guide will walk you through the principles of safe optical cleaning, from understanding why it’s so critical to executing a flawless cleaning procedure that preserves your valuable equipment.

Why Oil Stains Are a Unique Challenge

Understanding the enemy is the first step to defeating it. Oil stains pose a specific set of problems that differentiate them from dry particulate matter like dust.

Adhesion: Oils and fats are tenacious. They cling to glass surfaces, forming a thin, continuous film that bonds through van der Waals forces. Unlike dust, you can’t simply blow or brush them away without risk of scratching.

Light Scattering: A layer of oil turns a pristine, optically flat surface into a microscopic landscape of varying thickness. This causes light to scatter in unpredictable directions, drastically reducing contrast and system throughput. In imaging, this manifests as a loss of sharpness and increased haze.

Chemical Damage: Perhaps the most dangerous long-term threat is chemical etching. Certain oils, especially those from fingerprints which contain salts and acids from sweat, can react with anti-reflection coatings over time. This reaction can create permanent, etched stains that are impossible to remove, forever degrading the filter’s performance.

A Trap for Debris: An oily surface acts like a magnet for dust and other airborne particles. What starts as a small smudge can quickly become a grimy, abrasive slurry that is much harder to clean safely.

The goal, therefore, is not just to clean, but to clean in a way that removes the oil completely without leaving behind any residue or, worse, microscopic scratches.

The Golden Rule: Prevention is the Best Cure

The most effective strategy for dealing with oil on optical filters is to ensure it never gets there in the first place. Integrating simple handling protocols into your routine will save you countless hours of cleaning and protect your investment.

Master the Art of Handling: Always handle optical components by their edges. If the filter is mounted in a cell, handle the cell. For unmounted filters, consider wearing lint-free cotton or nitrile gloves. The goal is to never make contact with the polished surface.

Use a Dedicated Environment: When installing or removing filters, choose a clean, well-lit workspace. A clean desk is better than a cluttered, dusty one. Keep food, drinks, and tools with lubricants far away from your optical gear.

Protective Storage: When not in use, every filter should be stored in a dedicated, clean container. Anti-static plastic cases lined with foam or a proper filter wallet are ideal. This protects against physical impact, dust, and airborne contaminants.

The Right Tools for the Job: Keep a supply of essential cleaning tools handy: a rocket blower, optical cleaning fluid, and lens tissue or microfiber swabs. Being prepared means you’re less likely to use an inappropriate material like a shirt sleeve or a tissue in a moment of desperation.

Your Essential Optical Cleaning Toolkit

Before you begin any cleaning procedure, assemble your materials. Using the correct tools is non-negotiable. Substitutes like paper towels, facial tissue, or common window cleaner will almost certainly cause damage.

Compressed Gas/Rocket Blower: This is your first and most important tool. A rocket blower (a hand-squeezed bulb) is preferred over canned air, which can propel liquid propellant onto the surface.

Optical Cleaning Solvent: This is a specialized, high-purity fluid designed to dissolve oils and evaporate without leaving a residue. Common effective options include reagent-grade isopropyl alcohol (IPA), acetone, or dedicated optical cleaning solutions. A note of caution: Always verify that the solvent is compatible with your filter’s coatings. When in doubt, test on a very small area at the edge first. Acetone is a stronger solvent but can damage some plastics and older coatings.

Lint-Free Wipes: The application method is critical. Lint-free lens tissues or pre-packaged, pre-moistened optical wipes are the standard. High-quality microfiber cloths dedicated solely to optical cleaning can also be used, but they must be perfectly clean to avoid grinding trapped particles into the surface.

Swabs: For smaller filters or precise areas, foam-tipped or polyester-tipped optical swabs provide excellent control.

The Step-by-Step Guide to Safe Oil Removal

Follow this procedure meticulously. Do not rush. The entire process should be performed in a clean, dust-free environment.

Step 1: Initial Inspection and Dry Removal

First, use your rocket blower to remove any loose, dry particulate matter from the surface. Hold the filter vertically or at an angle so the blown debris falls away, rather than settling back onto another part of the surface. Examine the filter under a good light source to identify the oily areas. They will appear as smeary, rainbow-colored patches.

Step 2: Applying the Solvent

Do not apply solvent directly to the glass. Instead, apply a few drops to your lens tissue or moisten the tip of your swab. It should be damp, not dripping wet. Excess solvent can seep around the edges of the filter and into mounts, potentially causing other problems.

Step 3: The Cleaning Motion

Using the moistened tissue or swab, gently wipe the surface in a straight line from one edge to the other. Use very light pressure—you are wiping a fragile surface, not scrubbing a pan. After a single pass, rotate the tissue to a clean fold or use a new swab. Never use a circular “wax-on, wax-off” motion, as this can drag contaminants in a circle and grind them into the coating. Never wipe back and forth. A single, light, straight pass is the goal.

Step 4: Inspecting and Repeating

After the first pass, use your blower again to remove any potential lint (though there should be very little). Inspect the surface. If the oil stain persists, repeat the process with a fresh tissue and fresh solvent. It is always better to make multiple gentle passes than one aggressive one.

Step 5: Final Inspection

Hold the filter up to a light source at an angle. A perfectly clean surface will be invisible—you should see no streaks, smudges, or haze. If you see streaks, it typically indicates that a residue has been left behind, often from using too much solvent or an inappropriate cleaning agent. This would require another pass with a minimal amount of fresh solvent on a new tissue.

What to Absolutely Avoid

Certain actions will almost guarantee damage to your optical filter. Heed these warnings:

Never Wipe Dry: Never use a dry tissue or cloth to wipe a dry surface. Any microscopic dust particles will act like sandpaper against the soft coatings.

Avoid Harsh Chemicals: Household cleaners, Windex, solvents like paint thinner, or ethanol with denaturants contain additives, perfumes, and dyes that will leave a damaging film.

Don’t Use Excessive Pressure: Pressing hard will not make the oil come off faster; it will only increase the risk of grinding particles into the surface and creating scratches.

Don’t Breathe On It: The old technique of “huffing” on a lens to fog it up provides moisture for cleaning, but that moisture is also full of microscopic oil droplets from your breath and any residues in your mouth. It often makes the oil problem worse.

Conclusion: Clarity Through Care and Method

An oil stain on an optical filter is a problem, but it is rarely a catastrophe if approached correctly. The keys to success are a commitment to prevention, the use of proper materials, and the patience to follow a meticulous, gentle cleaning procedure. By respecting the delicate nature of these precision components, you can consistently restore their performance and ensure they continue to deliver the flawless optical clarity they were designed for.

Remember, the goal is not to achieve a sterile, laboratory-level clean with every wipe, but to remove the contaminant without introducing new damage. Integrating these practices into your workflow will transform optical maintenance from a dreaded chore into a simple, routine part of your craft, preserving the integrity of your gear and the quality of your work for years to come.

English

English 日本語

日本語 русский

русский Español

Español Deutsch

Deutsch 中文简体

中文简体

苏公网安备32041102000130号

苏公网安备32041102000130号