In the intricate world of precision optics, where the manipulation of light is measured in nanometers and arc-seconds, components are often celebrated for their complexity. We marvel at advanced lenses with countless elements, sophisticated diffractive optics, and cutting-edge metamaterials. Yet, sometimes, the most profound advancements come from perfecting the fundamentals. Among these foundational elements, the optical reflector stands as a silent, powerful workhorse. Far from being a simple mirror, the modern optical reflector is a feat of engineering that is fundamentally enabling progress across science and industry. From guiding lasers in futuristic manufacturing to capturing the faintest whispers of light from the edge of the observable universe, advanced reflector technology is quietly shaping the future of what is possible with light.

Beyond the Simple Mirror: What is an Optical Reflector?

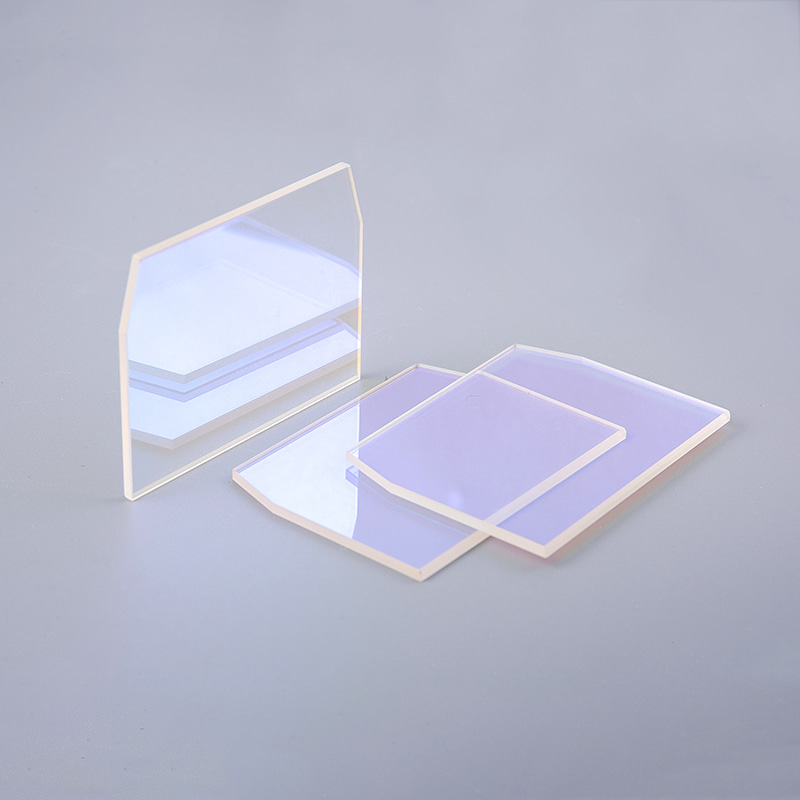

At its core, an optical reflector is any surface designed to redirect incident light. However, in precision optics, the term signifies a highly engineered component where performance is dictated by three critical parameters:

Reflectance: This is the efficiency of the reflector, measured as the percentage of incident light that is actually reflected. The goal is to minimize absorption and scattering losses. High-precision mirrors can achieve reflectance values of 99.999% or greater at specific wavelengths.

Surface Precision: This is often described by the surface flatness specification, measured in fractions of a wavelength (e.g., λ/10 at 632.8 nm). A surface that deviates by more than a fraction of the light’s wavelength will introduce aberrations, distorting the wavefront and degrading the quality of the optical system.

Surface Quality: This refers to micro-imperfections on the surface, like scratches and digs. These defects don’t necessarily alter the shape of the wavefront but cause scattered light, which reduces contrast and can create “ghost” images or noise in sensitive systems.

The combination of these factors determines a reflector’s suitability for high-performance optical systems, laser cavity mirrors, and astronomical instrumentation.

The Engine of Performance: Thin-Film Coating Technology

The transformative leap from a polished substrate to a functional optical reflector happens in the coating chamber. The development of advanced thin-film deposition techniques is the single greatest driver of progress in reflector technology. These processes involve vaporizing coating materials and depositing them atom-by-atom onto the optically polished substrate.

Key coating methods include:

Electron-Beam (E-Beam) Evaporation: A common method where an electron beam heats and vaporizes a source material inside a high-vacuum chamber. It allows for the deposition of a wide variety of materials and is excellent for producing high-quality dielectric mirror coatings.

Ion Beam Sputtering (IBS): This is a high-precision technique where an ion source bombards a target material, “sputtering” atoms onto the substrate. IBS produces extremely dense, stable, and low-scatter coatings with exceptional adherence and minimal absorption. It is the gold standard for creating ultra-high reflectance mirrors for demanding applications like gravitational wave interferometry.

Magnetron Sputtering: Similar in concept to IBS but uses powerful magnets to contain a plasma, increasing the deposition rate. It is highly scalable and reproducible, making it ideal for commercial and industrial volume production.

These techniques enable the creation of two primary types of reflective coatings:

Metallic Coatings: Traditional reflectors use thin layers of metals like aluminum, silver, and gold. Each has its advantages: aluminum offers broad spectral coverage from the UV to IR, silver provides the highest reflectance in the visible to near-IR spectrum, and gold is exceptional for infrared applications. However, metallic coatings inherently have higher absorption losses than dielectric alternatives.

Dielectric Coatings: These are constructed by depositing multiple alternating layers of two materials with different refractive indices (e.g., silicon dioxide and tantalum pentoxide). Through constructive interference, these layers can be tuned to achieve reflectances of 99.99% or higher at a specific wavelength or band. They offer superior performance but are typically more sensitive to the angle of incidence and have a narrower bandwidth than metallic coatings. Developments in broadband dielectric mirror design are continually pushing these limitations.

Key Applications Driving Innovation

The demand for better, more reliable, and more specialized optical reflectors is fueled by their critical role in several frontier technologies.

1. Laser Systems and Photonics

The field of photonics is arguably the most significant driver of reflector innovation. Laser optic mirrors form the resonant cavity of every laser, and their quality directly determines the laser’s output power, beam quality, and stability.

High-Power Laser Applications: In industrial laser cutting, welding, and ablation, reflector coatings must handle immense power densities without thermal deformation (thermal lensing) or damage. This requires not just high reflectance but also excellent thermal stability and management, often achieved with ultra-low loss coatings and specialized substrate materials like silicon or copper.

Precision Metrology: Interferometers, the workhorses of precision measurement, rely on reflectors to split and recombine light beams. The sensitivity of these devices, used for measuring everything from machine part flatness to gravitational waves, is directly dependent on the reflector’s surface flatness and coating consistency.

2. Astronomy and Space Exploration

Astronomy constantly pushes the limits of optical technology. The pursuit of fainter, more distant objects requires larger telescopes that collect more light. This has led to the development of massive precision astronomical mirrors. Modern telescopes no longer use monolithic glass mirrors but instead employ segmented reflector systems, like those on the James Webb Space Telescope (JWST). Each segment is a masterpiece of optics, featuring exquisite surface figure accuracy and specialized coatings (JWST’s gold coating is optimized for the infrared spectrum). The future of ground-based astronomy, with Extremely Large Telescopes (ELTs), depends entirely on the ability to manufacture and align hundreds of these segmented reflectors.

3. Semiconductor Lithography

The creation of ever-smaller computer chips relies on lithography machines that use extreme ultraviolet (EUV) light. At these tiny wavelengths, all materials are highly absorptive, making refractive lenses impractical. Therefore, EUV lithography systems are entirely reflective, using intricate assemblies of multilayer EUV mirrors. These mirrors are among the most technically challenging objects ever manufactured, requiring atomic-level smoothness and precise multilayer coatings that can work at angles of incidence never used in traditional optics. The entire semiconductor industry hinges on the perfection of these reflectors.

4. Telecommunications

The global network of fiber-optic internet depends on light signals traveling through glass fibers. Over long distances, these signals need to be amplified. This is achieved using Dichroic Reflectors and Thin-Film Filters within Erbium-Doped Fiber Amplifiers (EDFAs). These reflectors must precisely separate pump laser light from the signal light with incredible efficiency, ensuring data integrity across thousands of kilometers.

5. Life Sciences and Medical Imaging

Advanced microscopes, such as confocal and multi-photon microscopes, use dichroic mirrors to separate different wavelengths of fluorescence light with high precision. This allows researchers to tag and image multiple cellular structures simultaneously. The clarity and contrast of the resulting images are a direct result of the quality of these specialized reflectors.

The Manufacturing Edge: Polishing and Metrology

Advanced coatings can only perform as well as the substrate they are applied to. The manufacturing of the reflector substrate itself has seen significant advancements.

Computer-Controlled Polishing: Modern polishing uses CNC machines that can deterministically figure a glass or ceramic substrate to achieve unparalleled surface flatness, moving beyond λ/20 to λ/50 and even better for the most demanding applications.

Advanced Metrology: You cannot make what you cannot measure. The development of laser interferometry and phase-shifting interferometry allows manufacturers to map a surface’s topography with sub-nanometer precision. This data directly feeds back into the polishing process, creating a feedback loop that drives perfection.

This synergy between polishing and measurement is crucial for producing low-wavefront distortion mirrors essential for any high-resolution imaging or precision laser system.

Future Trends and Developments

The evolution of optical reflectors is far from over. Several exciting trends point toward the future:

Enhanced Laser Damage Threshold (LDT): As lasers continue to increase in power, particularly with the advent of ultrafast pulsed lasers, the need for coatings that can withstand extreme peak powers is paramount. Research into new material combinations and coating architectures is ongoing to push LDT limits further.

Active and Adaptive Optics: Reflectors are becoming “smart.” Large ground-based telescopes use deformable mirrors with hundreds of actuators on their back surface. These actuators can adjust the mirror’s shape thousands of times per second to counteract atmospheric turbulence, providing crystal-clear images from Earth. This technology is now trickling down into other fields, including ophthalmology for imaging the retina and laser communications.

Structured and Functionalized Surfaces: The line between reflective and diffractive optics is blurring. Reflectors are being combined with nanostructures to create hybrid components with unique properties, such as polarizing beam splitters or mirrors that reflect light at a specific angle regardless of the angle of incidence (retroreflectors).

Material Science Innovations: Research into new substrate materials like silicon carbide (SiC), which offers a superb stiffness-to-weight ratio and thermal stability, is enabling lighter, more stable mirrors for space-based applications.

Conclusion: A Reflective Foundation for the Future

While often operating behind the scenes, the optical reflector is a cornerstone of modern technology. Its journey from a simple polished metal surface to a complex, nano-engineered component mirrors the broader trajectory of precision optics itself. The relentless pursuit of higher reflectance, perfect surface form, and greater environmental durability in these components is not an isolated engineering challenge; it is a fundamental enabler.

The next generation of scientific discoveries, from observing the first stars to understanding the fundamental forces of the universe, will be seen through these highly reflective surfaces. The next waves of industrial innovation, in manufacturing and communications, will be guided by them. In mastering the reflection of light, we are not just looking back at ourselves; we are projecting our capabilities forward, illuminating a path toward a more precise, connected, and insightful future. The humble reflector, in its perfected form, remains an indispensable tool in shaping that future.

English

English 日本語

日本語 русский

русский Español

Español Deutsch

Deutsch 中文简体

中文简体

苏公网安备32041102000130号

苏公网安备32041102000130号