The rise of LED (Light Emitting Diode) technology represents one of the most significant leaps forward in lighting efficiency. LEDs themselves are inherently efficient, converting a much higher percentage of electrical energy into visible light than incandescent or fluorescent sources. However, the raw light emitted from an LED chip is only the beginning of the story. A substantial portion of its potential can be wasted if not properly controlled and directed. This is where the often-overlooked but critical component, the optical reflector, comes into play. By mastering the physics of light direction, optical reflectors are fundamental in transforming raw LED emission into usable, efficient, and application-specific illumination.

Understanding the Core Challenge: LED Light Distribution

To appreciate the role of the reflector, we must first understand the native behavior of an LED. A bare LED semiconductor chip typically produces a lambertian emission pattern. This means it emits light in a broad, hemispherical spread, with intensity following the cosine of the angle from the normal (perpendicular). In simpler terms, it’s brightest looking straight down at the chip and dims towards the sides.

For many applications, this wide, uncontrolled spread is problematic:

- Energy Waste: Light spills into areas where it is not needed (e.g., into ceiling cavities, back into the fixture housing, or sideways into glare zones).

- Reduced Effectiveness: The illuminance (light level on a task) is lower because the luminous flux is diluted over a large area.

- Glare: Uncontrolled side-emission can cause visual discomfort for users.

The primary job of an optical reflector, in conjunction with other optics like lenses and diffusers, is to solve this problem by collecting, redirecting, and shaping this raw light output. The efficiency gain is realized by minimizing losses and ensuring that a maximal percentage of the generated photons end up precisely where they are intended.

The Mechanisms of Efficiency Improvement

The efficiency contribution of an optical reflector can be broken down into several key physical and geometric principles:

1. Light Collection and Reduction of Trapped Light:

Inside a lighting fixture, light emitted backwards or at high angles from the LED can strike the housing or heat sink and be absorbed, converting into wasted heat. A well-designed reflector, often shaped as a cavity or cup surrounding the LED, intercepts this otherwise “lost” light. Its surfaces are engineered to redirect these rays forward, into the desired beam path. This directly increases the luminous efficacy of the system—more lumens exit the fixture per watt of electrical input.

2. Beam Shaping and Control:

This is the most visible function. Reflectors contour the raw light into specific photometric distributions. Common patterns include:

- Spot (Narrow Beam): Deep, parabolic-shaped reflectors capture wide-angle rays and collimate them into a tight beam for accent lighting or task lighting.

- Flood (Wide Beam): Shallower reflectors provide a gentler redirection, creating a broad, even wash of light for area illumination.

- Asymmetric (e.g., Wall Wash, Roadway): Sophisticated free-form or faceted reflectors are designed using complex algorithms to “sculpt” light, projecting it into precise rectangular patterns, shielding it from certain angles, or distributing it evenly across a vertical surface. By eliminating spill light outside the target zone, this control represents a massive efficiency gain for the application.

3. Optical Material Efficiency: Reflectance is Paramount

The material and coating of the reflector are its engine. Efficiency is quantified by its total reflectance—the percentage of incident light that is reflected.

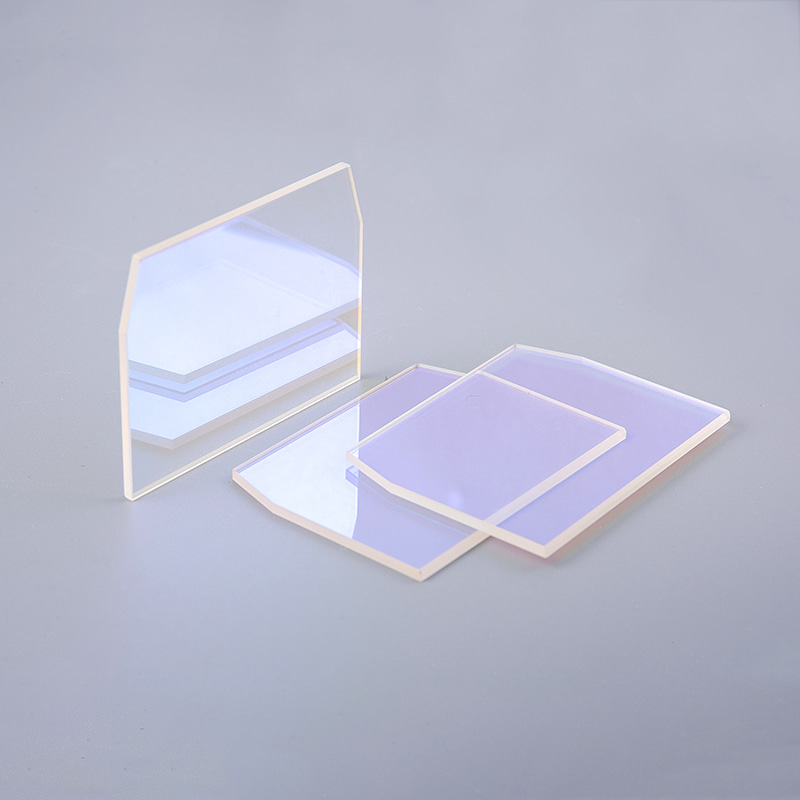

- Specular Reflectors: These have mirror-like, smooth surfaces. They maintain the directionality of light rays (following the law of reflection: angle of incidence equals angle of reflection). High-quality specular reflectors, using materials like anodized aluminum (with reflectance of ~85-89%) or enhanced silver-coated polymers (with reflectance reaching 95-98%), are the standard for high-efficiency LED optics. The choice involves a trade-off between cost, durability, and that crucial reflectance percentage. A 5% increase in reflectance can translate to a measurable gain in overall fixture output.

- Diffuse Reflectors: These have matte or textured surfaces that scatter light. While they don’t provide precise beam control, they are excellent for reducing glare and creating very soft, even illumination by mixing light within a cavity (as seen in indirect fixtures or backlights). Their efficiency comes from high hemispherical reflectance and reducing hotspots.

4. Faceted and Textured Designs for Uniformity:

A perfectly smooth specular reflector can produce sharp, uneven beam patterns with artifacts like rings or hard edges. To mitigate this, many modern reflectors incorporate micro-facets, textures, or orange-peel patterns. These subtle surface variations homogenize the light by providing a tiny amount of diffusion, blending multiple ray paths to create a smoother, more uniform beam with a consistent color appearance—a key aspect of quality and perceived efficiency. This minimizes the need for additional diffusing elements, which typically absorb 10-20% of the light.

5. Thermal and Longevity Benefits:

While not a direct optical function, a reflector’s role in system efficiency extends to thermal management. By allowing light to escape the fixture more directly, it reduces the amount of radiant energy absorbed by internal components. Lower operating temperatures prolong the lifespan and maintain the light output (lumen maintenance) of the LEDs and drivers. An inefficient optical system that traps light effectively turns the fixture into a small oven, degrading performance over time.

Real-World Applications and Efficiency Gains

The impact of reflector design is evident across industries:

- Commercial Downlights: Modern LED downlights use deep, specular reflectors to create sharp cutoff angles, preventing ceiling glare (“cave effect”) and delivering light efficiently to the work plane, often exceeding 90% optical efficiency (percentage of LED lumens that exit the fixture).

- Street and Area Lighting: Asymmetric reflectors are critical. They direct light onto the road and sidewalk while strictly minimizing light trespass (light falling onto neighboring properties) and skyglow (light directed upwards). This ensures almost all consumed power is used for its intended purpose, enhancing public safety while reducing energy waste and environmental light pollution.

- Retail and Museum Lighting: Precise elliptical or parabolic reflectors create crisp, controlled beams to highlight merchandise or artwork with minimal spill. This allows for lower-wattage LEDs to achieve the same visual impact, a direct efficiency win.

- Automotive Headlights: Complex multi-reflector assemblies collect light from high-power LED chips and form it into the legally required low-beam and high-beam patterns with extreme precision, maximizing seeing distance for safety while avoiding glare for oncoming drivers.

Design Considerations and Trade-offs

Implementing an optical reflector is not without its challenges. Designers must balance:

- Efficiency vs. Beam Quality: The pursuit of absolute maximum efficiency (e.g., a perfect parabolic mirror) might result in a beam with artifacts. Some diffusion may be sacrificed for aesthetic uniformity.

- Size Constraints: Achieving tight beam control often requires a deeper reflector. Fixture form factors (like ultra-slim panels) may limit optical depth, forcing compromises or alternative solutions like lens optics.

- Cost vs. Performance: Enhanced silver coatings offer the highest reflectance but at a higher cost than anodized aluminum. The choice depends on the efficiency target and price point of the final product.

Conclusion: A Symbiotic Relationship

To state that optical reflectors “improve” the efficiency of LED lights is almost an understatement. They are an enabling technology that allows the inherent efficiency of the semiconductor to be translated into effective, applied efficiency in the real world. They act as the conductors of a light orchestra, ensuring each photon plays its part in the final illumination scene.

While the LED is the source, the optical reflector is the indispensable director. It minimizes waste, tailors light to the exact needs of the space, enhances visual comfort, and ultimately ensures that the revolutionary promise of LED technology—doing more with less energy—is fully realized. In the continuous pursuit of sustainable lighting, advancements in reflector design, materials, and manufacturing (such as injection molding and diamond-turned machining) will continue to push the boundaries, extracting ever more useful light from every single watt of power consumed.

English

English 日本語

日本語 русский

русский Español

Español Deutsch

Deutsch 中文简体

中文简体

苏公网安备32041102000130号

苏公网安备32041102000130号