Optical reflectors are essential components in numerous light-based systems, from simple flashlights to advanced laser equipment. This guide provides practical information to help you understand, select, and utilize optical reflectors effectively in your projects.

What is an Optical Reflector?

An optical reflector is a surface designed to redirect light waves according to the laws of reflection. These specialized components are crucial for controlling light paths in optical systems while minimizing energy loss. Unlike regular mirrors, optical reflectors are engineered for specific wavelength ranges and often feature specialized coatings.

Primary Types of Optical Reflectors

1. First Surface Reflectors

These high-precision reflectors have the reflective coating applied to the front surface, eliminating ghost images caused by secondary reflections. They're ideal for laser systems and scientific instruments where accuracy is critical.

2. Second Surface Reflectors

Common in everyday mirrors, these have the reflective coating behind the glass. While more durable, they're less precise due to potential refraction at the air-glass interface.

3. Dichroic Reflectors

These advanced reflectors use thin-film interference to selectively reflect certain wavelengths while transmitting others. They're valuable in fluorescence microscopy and specialized lighting applications.

4. Parabolic Reflectors

Featuring a precise parabolic shape, these reflectors collimate light from a focal point or focus parallel rays to a single point. Common in spotlights and satellite dishes.

5. Elliptical Reflectors

With two focal points, these reflectors transfer light efficiently between them. Frequently used in medical devices and fiber optic illumination systems.

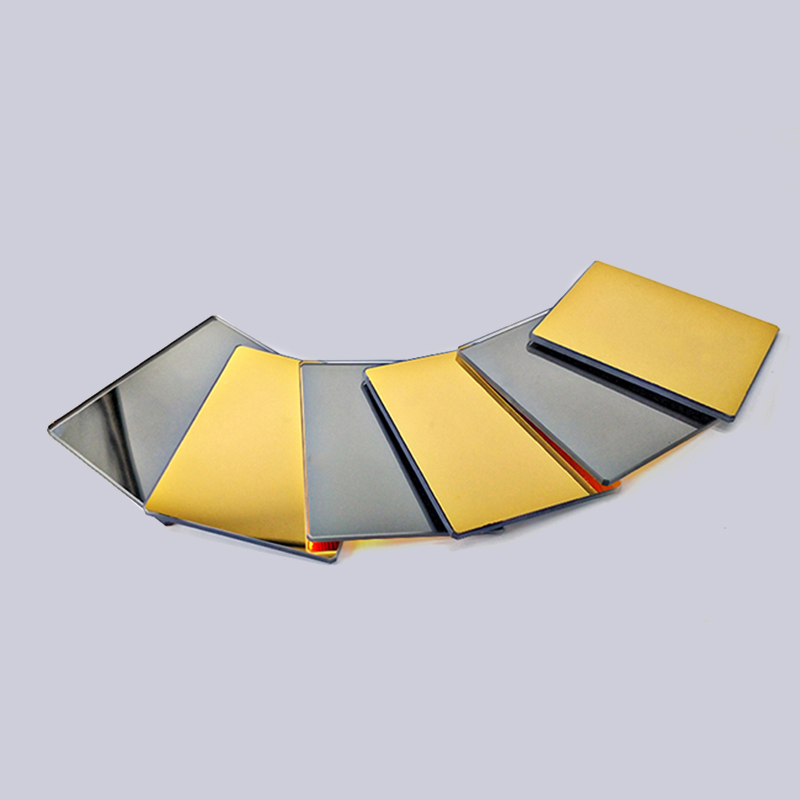

Optical Reflector Performance Comparison

| Reflector Type | Reflectivity (%) | Optimal Wavelength Range | Typical Applications | Cost Range |

| Aluminum Coated | 85-92 | UV to Far IR | General purpose, telescopes | $ |

| Silver Coated | 95-98 | Visible to Near IR | High-end optics, spectroscopy | $$ |

| Dielectric | 99+ | Narrow bands | Lasers, precision instruments | $$$ |

| Gold Coated | 95-98 | Near to Far IR | Infrared systems, thermal imaging | $$ |

Key Applications of Optical Reflectors

Laser Systems

High-reflectivity mirrors are critical components in laser cavities, beam steering, and optical amplification systems. Dielectric reflectors with >99.9% reflectivity at specific wavelengths are commonly used.

Photovoltaic Systems

Concentrated solar power plants use large parabolic reflectors to focus sunlight onto receivers, significantly increasing energy conversion efficiency.

Keyword-rich paragraph: "When searching for high-efficiency solar reflectors or durable optical mirrors for outdoor use, consider aluminum-coated reflectors with protective layers that resist environmental degradation while maintaining reflectivity above 85% across the solar spectrum."

Automotive Lighting

Modern headlights utilize complex reflector designs to shape light beams according to safety regulations while maximizing luminous efficiency.

Medical Equipment

From dental curing lights to surgical illumination systems, optical reflectors ensure precise light delivery where it's needed most.

How to Choose the Right Optical Reflector

1. Consider Your Wavelength Requirements

Different coatings perform optimally in specific ranges. Aluminum works broadly from UV to IR, while gold excels in infrared applications.

2. Evaluate Angle of Incidence

Reflectivity often changes with incident angle. For 45-degree beam splitters or low-angle reflectors, verify performance at your working angles.

3. Assess Environmental Factors

Humidity, temperature fluctuations, and chemical exposure may dictate protective overcoat requirements. For harsh environments, consider protected silver coatings or dielectric stacks.

4. Determine Surface Accuracy Needs

Precision optics require λ/10 or better surface accuracy, while general lighting applications may tolerate λ/2 surfaces.

5. Calculate Cost vs Performance

While dielectric coatings offer superior reflectivity, aluminum coatings often provide the best value for broad-spectrum applications.

Maintenance and Handling Tips

Proper care extends reflector lifespan and maintains optical performance:

- Always handle by the edges to avoid coating damage

- Use compressed air or lens tissue for cleaning - never wipe dry

- Store in low-humidity environments with protective covers

- For first surface mirrors, avoid any contact with the reflective coating

- Inspect regularly for oxidation or delamination signs

Emerging Trends in Reflector Technology

Ultra-Broadband Coatings

New coating designs achieve >95% reflectivity from UV to mid-IR, simplifying multispectral systems.

Lightweight Composite Materials

Advanced polymers with metallic coatings enable large, low-mass reflectors for aerospace applications.

Active Shape Control

Adaptive optics incorporate actuators to dynamically correct reflector shape, maintaining focus in variable conditions.

Self-Cleaning Surfaces

Nanostructured coatings that repel dust and moisture are revolutionizing outdoor optical reflector applications.

Frequently Asked Questions

What's the difference between protected and enhanced aluminum coatings?

Protected aluminum has a durable overcoat preventing oxidation, while enhanced aluminum includes additional dielectric layers to boost specific wavelength reflectivity.

How often should optical reflectors be replaced?

With proper care, high-quality reflectors last 5-10 years. Monitor performance degradation through regular efficiency measurements.

Can damaged reflector coatings be repaired?

While small defects can sometimes be masked, most coating damage requires complete stripping and recoating by a specialist facility.

What are the best reflectors for UV applications?

For UV systems, consider magnesium fluoride-protected aluminum or specialized dielectric coatings optimized for your target wavelengths.

Conclusion

Selecting the right optical reflector requires careful consideration of your specific wavelength, environmental, and performance requirements. By understanding the different types, coatings, and applications covered in this guide, you can make informed decisions that optimize your optical systems' performance and longevity. Whether you're working with precision laser optics or commercial lighting reflectors, the proper reflector choice can significantly impact your project's success.

English

English 日本語

日本語 русский

русский Español

Español Deutsch

Deutsch 中文简体

中文简体

苏公网安备32041102000130号

苏公网安备32041102000130号